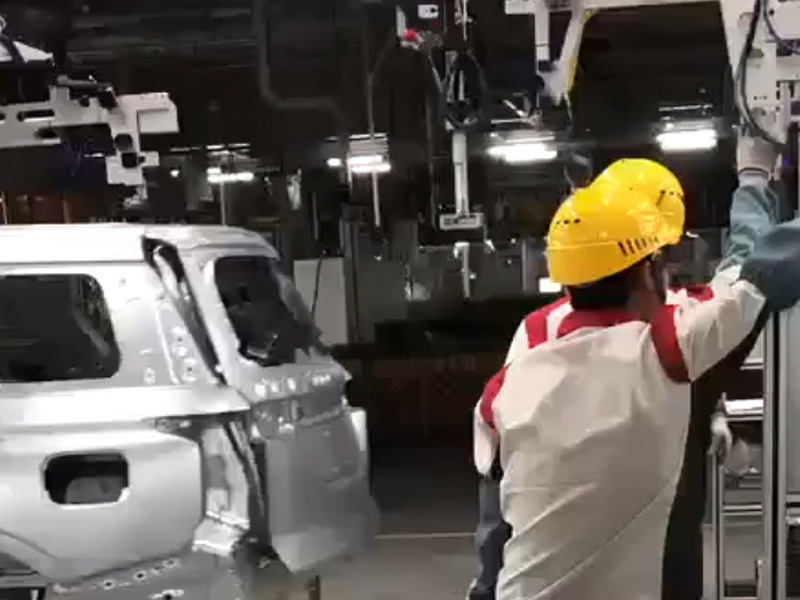

This project is a professional support equipment transformation project for the final assembly workshop of the automobile manufacturer Changsha Plant No. 3. The project includes 16 sets of support equipment and 29 sets of anti-torsion arm equipment for the front and rear suspension assembly lines. The door assembly robotic arms and reaction arms are made of carbon fiber material, which has excellent properties such as high toughness and lightweight. This project will be installed in the factory in December 2023, with on-site installation and debugging completed by June 2024.

Learn moreThis project involves the welding fixtures for the automotive manufacturer’s factory in Xiangyang, including the adaptation of new models and the addition of new fixtures. The project includes 10 sets of equipment such as front cover fixtures, side wall fixtures, and side wall assembly fixtures. The design was completed in September 2023, and the equipment was delivered to the site for installation and debugging in November. With rich experience in welding fixtures for sheet metal white body types, we offer customized design and quick delivery. This project has now completed final acceptance.

Learn moreThis project involves more than 100 sets of anti-twist arm equipment, over 200 sets of controller brackets, and 12 tire tightening machines located at three bases in Jinan, Zhengzhou, and Uzbekistan for automotive manufacturers. It features standardized structural design, is lightweight, and easy to maintain.

Learn moreThis project is a new construction project for the welding line in the welding workshop of the Jingmen automobile manufacturer. The welding line project is divided into four subcontracting packages, with the scope of each package as follows: Main welding line: includes the main line body (UB, MB), top cover line, grippers, body fixtures, manual fixtures, and other tooling equipment to achieve multi-model co-line production.

Learn moreThis project is a production enhancement project for the assembly of Guangzhou automobile manufacturers, focusing on the transformation of specialized assistive equipment. The project includes 17 sets of assistance for sunroof installation, instrument installation, door installation, sunroof repair, door disassembly, front module assistance, front seat robotic assistance, and large battery installation. Additionally, it involves the modification and addition of 33 sets of anti-torsion arm equipment for the front and rear suspension assembly lines and chassis assembly lines.

Learn moreThis project involves an automatic loading and unloading robotic arm for SPS material vehicles at domestic automotive manufacturers. It covers an area of 9m x 5m and can move in the X and Y directions. The track is equipped with corresponding detection switches to accurately control the start and stop positions of the equipment, allowing AGV to automatically transfer materials to the main line side, achieving unmanned automated production.

Learn moreThis project is a professional support equipment project for the final assembly workshop of a domestic automotive manufacturer in Thailand. The project includes 10 sets of support equipment for sunroof installation, door installation, instrument installation, front seat installation, etc., as well as 9 sets of hoisting equipment for power batteries in the front and rear suspension assembly areas, and 12 sets of anti-twist arm equipment for the chassis line assembly line. The design of this project started at the end of November 2023, and within one month in December, the entire project processing and production were completed. After-sales personnel will be arranged for on-site installation and debugging during the Chinese New Year in 2024 to successfully complete the project milestone tasks.

Learn more