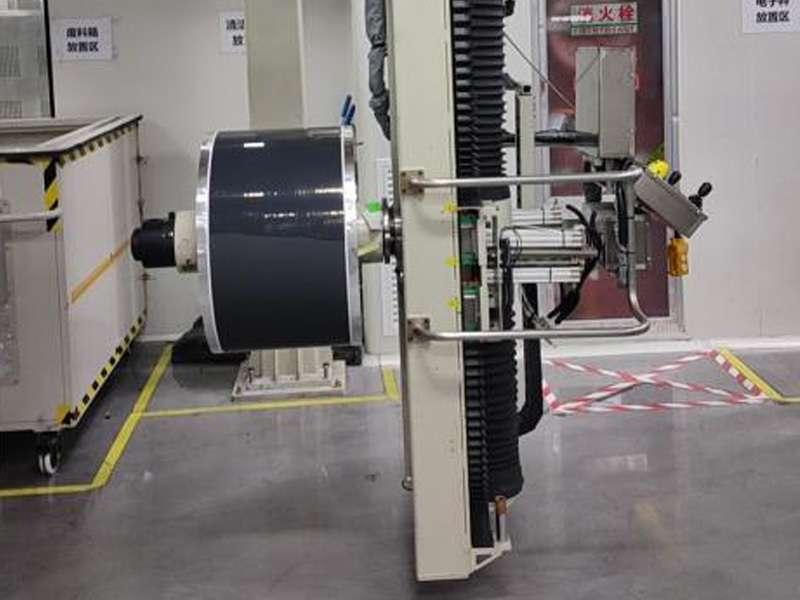

This project is for the OHT (Overhead Transport) arm project at a new energy vehicle factory in Jiangsu. The OHT glides on an elevated track, with servo motors driving the X/Y direction (parallel to the ground). It is controlled via a joystick, and during operation, the acceleration and deceleration processes must effectively prevent impacts.

Learn moreThis project is for the assembly equipment of fenders, hoods, front doors, and tailgates for a vehicle model at a main automotive manufacturer in Chongqing. To ensure the assembly accuracy of fenders, hoods, front doors, and tailgates with the vehicle body, the equipment is manually adjustable. This project features high precision and heavy load capacity equipment independently developed by the company. The main structure uses aluminum profile T-shaped mainframe combined with cylinder control for vertical stroke range and multiple action steps to complete the assembly equipment, ensuring that the assembly accuracy of workpieces meets production requirements. This project was completed with on-site installation and debugging in April 2024 and has been delivered for customer use.

Learn moreThis project involves the transplanting of PICK UP conveyor scissor forks for domestic host manufacturers. It uses a motor for movement and a scissor fork belt that can extend and retract vertically, allowing for precise material picking and transplanting to the tooling table at designated points. The project will be delivered within a one-month period, with on-site electrical commissioning and interaction completed within a week.

Learn moreThis project involves the loading and unloading of a mechanical arm and truss in the scissor lift workshop of an engineering machinery factory in Wangcheng District, Changsha, Hunan. The project includes 4 sets of fork arm sorting truss equipment, 1 set of ground column counterweight transfer mechanical arm, and 1 set of off-road tire bolt tightening equipment. All have been installed, debugged, and are now in use on site. Among them, the 4 sets of fork arm sorting truss equipment utilize a truss system developed by the company, which includes an XYZ three-axis servo drive system paired with a Mech-Mind visual positioning system to ensure the accuracy of material picking order and tray positioning.

Learn more