Products

Focus on the design, manufacture and service of power-assisted manipulators, intelligent production lines, customized special machines, truss robots and robot workstations.

T Manipulator

T-type manipulator is an important branch of the manipulator family, simple structure, lightweight and easy to operate, through the cooperation of the electrical can be easier to achieve automation; different from the traditional manipulator, beautiful, lightweight, simple structure, easy to install and maintain, easy to locate, easy to achieve automation.

Wuhan Furuili Automation Equipment Co., Ltd

Wuhan Furuili Automation Equipment Co., Ltd. is located in Chenggong Industrial Park, No. 176 Checheng East Road, Wuhan Economic and Technological Development Zone, Hubei Province. It focuses on the design, manufacture and service of power-assisted manipulators, intelligent production lines, customized special machines, truss robots and robot workstations, as well as the research and development and sales of supporting information systems. It is an enterprise that can provide customized and intelligent solutions for industrial production.

The company is recognized by "small and medium-sized enterprises of science and technology", "innovative small and medium-sized enterprises" and "high-tech enterprises.

Registered capital

Number of employees

Sales

Why choose us

Provide customized, intelligent industrial production solutions

Enterprise strength

The company has a total area of 10000 square meters, including: office building area of 1500 square meters; production area (including testing and warehouse) of 8500 square meters; 2 invention patents, 3 invention patents under substantive examination; 11 utility model patents;

Quality Management

As of August 24, the total number of people is 158, and the technical center has 47 people, including 33 people in the first part and 14 people in the second part; 44 people in production and quality; 26 people in after-sales service and 60 people in the third party of strategic cooperation;

After-sales service

The department has 26 after-sales personnel and 14 with more than 7 years of working experience. There are about 60 third-party resources available for long-term cooperation. We attach importance to every detail and make your after-sales experience impeccable.

cases

Become a healthy non-standard intelligent equipment provider

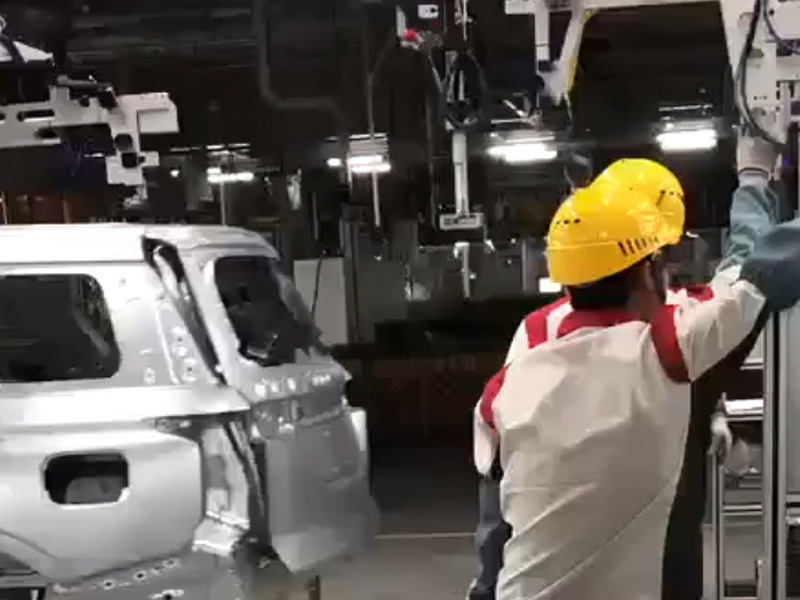

This project is a professional support equipment transformation project for the final assembly workshop of the automobile manufacturer Changsha Plant No. 3. The project includes 16 sets of support equipment and 29 sets of anti-torsion arm equipment for the front and rear suspension assembly lines. The door assembly robotic arms and reaction arms are made of carbon fiber material, which has excellent properties such as high toughness and lightweight. This project will be installed in the factory in December 2023, with on-site installation and debugging completed by June 2024.

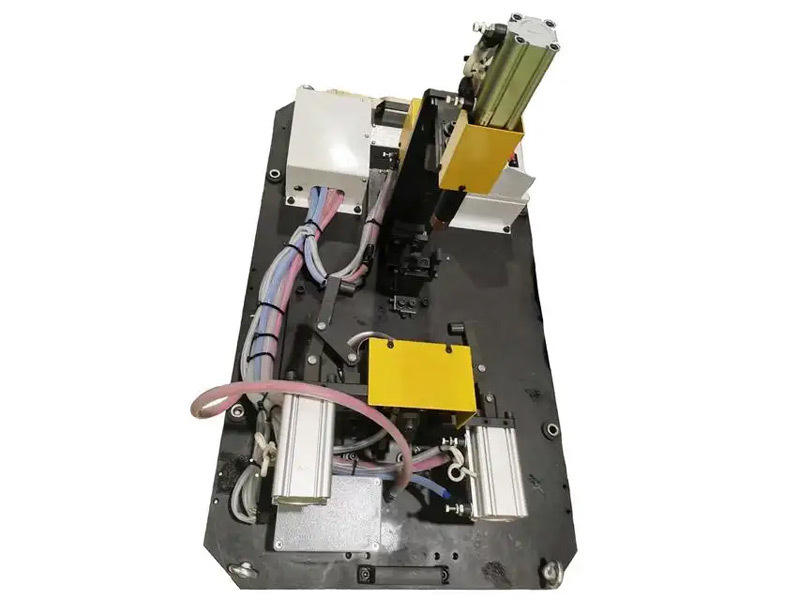

Learn moreThis project involves the welding fixtures for the automotive manufacturer’s factory in Xiangyang, including the adaptation of new models and the addition of new fixtures. The project includes 10 sets of equipment such as front cover fixtures, side wall fixtures, and side wall assembly fixtures. The design was completed in September 2023, and the equipment was delivered to the site for installation and debugging in November. With rich experience in welding fixtures for sheet metal white body types, we offer customized design and quick delivery. This project has now completed final acceptance.

Learn moreThis project is a professional support equipment transformation project for the final assembly workshop of the automobile manufacturer Changsha Plant No. 3. The project includes 16 sets of support equipment and 29 sets of anti-torsion arm equipment for the front and rear suspension assembly lines. The door assembly robotic arms and reaction arms are made of carbon fiber material, which has excellent properties such as high toughness and lightweight. This project will be installed in the factory in December 2023, with on-site installation and debugging completed by June 2024.

Learn moreThis project involves the welding fixtures for the automotive manufacturer’s factory in Xiangyang, including the adaptation of new models and the addition of new fixtures. The project includes 10 sets of equipment such as front cover fixtures, side wall fixtures, and side wall assembly fixtures. The design was completed in September 2023, and the equipment was delivered to the site for installation and debugging in November. With rich experience in welding fixtures for sheet metal white body types, we offer customized design and quick delivery. This project has now completed final acceptance.

Learn moreThis project involves more than 100 sets of anti-twist arm equipment, over 200 sets of controller brackets, and 12 tire tightening machines located at three bases in Jinan, Zhengzhou, and Uzbekistan for automotive manufacturers. It features standardized structural design, is lightweight, and easy to maintain.

Learn moreThis project is a new construction project for the welding line in the welding workshop of the Jingmen automobile manufacturer. The welding line project is divided into four subcontracting packages, with the scope of each package as follows: Main welding line: includes the main line body (UB, MB), top cover line, grippers, body fixtures, manual fixtures, and other tooling equipment to achieve multi-model co-line production.

Learn moreBLOG

Pay attention to us, understand the latest product dynamics, enterprise dynamics, etc.

Construction field: Carbon fiber products are used to strengthen the concrete structure and improve the seismic and wind-resistant performance of buildings.

Learn moreThe design and production of the mold should ensure the precision and surface quality to ensure the molding quality of the products.

Learn moreFamiliarize with the structure and adjustment method of the tooling: Before adjusting the tooling, the operator should familiarize himself with the structure, performance and adjustment method of the tooling, and follow the relevant operation manual and work instructions.

Learn moreBefore the angle adjustment of work screws, we must first understand the basic knowledge and nature of the screw, such as the material, specifications, length of the screw, etc.. This basic knowledge helps to better select the adjustment method and tools.

Learn morePartner

Provide customized, intelligent industrial production solutions